A Variety of Materials are capable of being processed:

AHSS — Advanced High Strength Steel

Cold Rolled

CR Motor Lamination

CRNO (Non-Oriented)

Martensite

CR CSB / DS / DDS / EDDS

Aluminum

Coated

Embossed Steel

Laminated Materials

Stainless

Pre-Painted

H.D. Galvanized

Electro Galvanized

Tin Mill Products

High Carbon

H.R. Pickled and Oiled

AHSS – Advanced High-Strength Steel

Arlington Metals is the leader in AHSS slitting. This process requires not only specialized equipment, but also unique tooling and set-up techniques to yield a superior slit edge. As the automotive and other industries seek to provide Battery Electric Vehicles (BEV) and other cutting-edge modes of transportation, AHSS will continue to provide the necessary weight saving, while maintaining the required strength for the end-use product.

Critical Surface / Pre-Painted Slitting

By utilizing five Herr Voss 19 roll – 5 high Strand Extensioners or non-marring tension pads or tension rolls, Arlington Metals processes critical surface material such as; pre-painted, aluminum, galvanized, etc. Critical surface and shape slitting via our Strand Extensioning process is what we coined: “tension levelled – slit last coils.” If shape is a concern and you have a specific I-Unit requirement, then our Strand Extensioning process is the perfect solution. Other specialty techniques include the aid of Unilux strobe lights along with high intensity LED and Halogen inspection lighting for 2-sided “CLASS AA / CLASS 1” automotive inspection. This coupled with the proper chalking or stoning inspection practices, yields superior results.

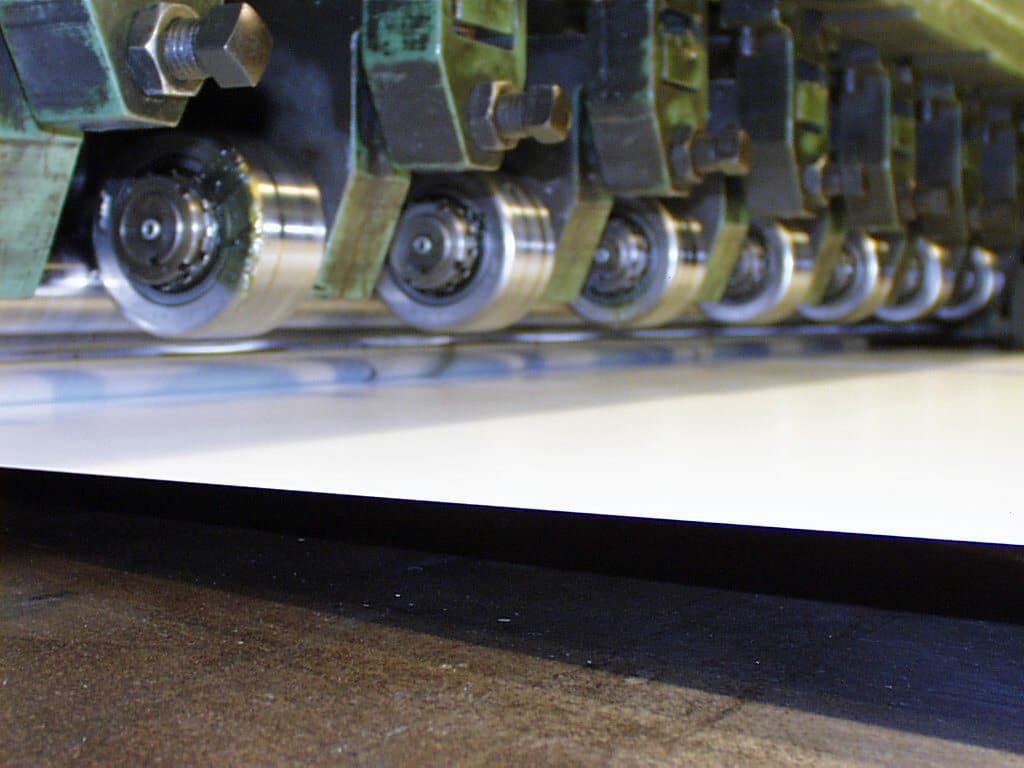

Loop Slitting

Our gauge ranges not only go down to .007″ in thickness with slit widths down to .300″, but wide our array of slitting lines permit us to slit to width tolerances of + – .002″.

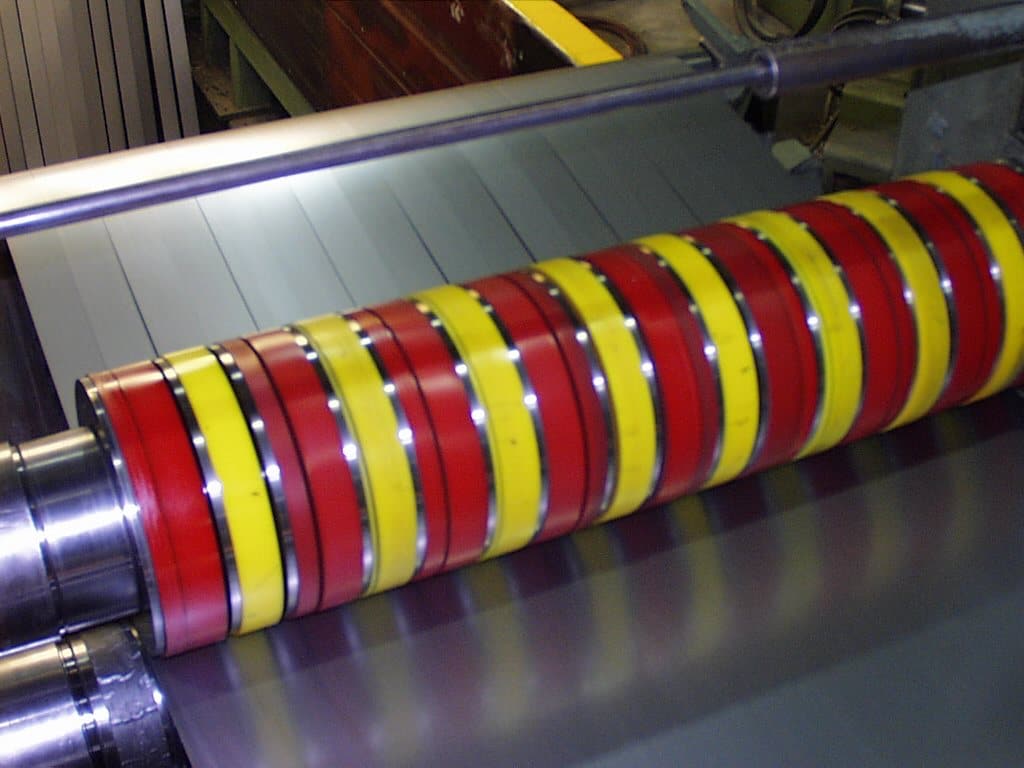

Narrow Slitting

Arlington Metals has the capability to process very narrow slit mults down to .300″ wide. It is common for us to process up to 19 narrow mults in one set-up. Our robust 24″ slitter performs a beautiful job time and time again.